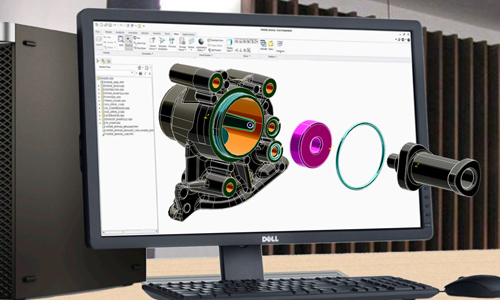

Development

Co-Development

Through a complete customer support, PERNAT Industrie is able to ensure the co-conception of complex products including assemblies

Process Development

Technical teams within Pernat organisation has the capacity to develop and integrate :

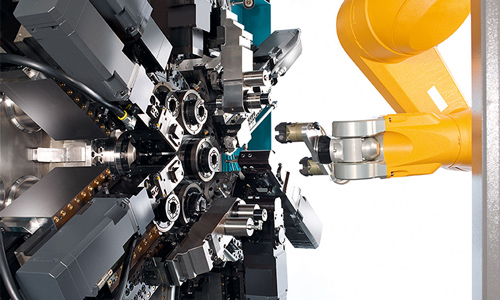

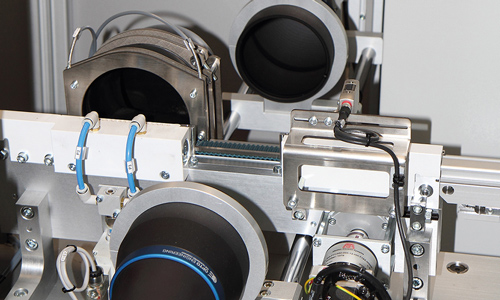

- Tooling and assembly systems

- Robotised Cells

Process - Machines

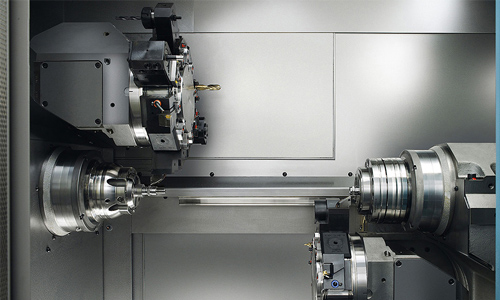

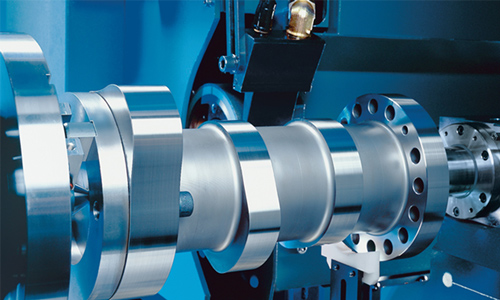

Screw-Turning / Machining

Screw-Turning Multispindle

- Multispindle lathes (6-8 bars) traditional : Wickman, Mori-Say, Index

- Multispindle lathes (6-8 barres) CNC : Index MS, TMZ

Screw-Turning

- Monospindle lathes CN with sliding headstock : Traub, Tornos Deco

- Monospindle lathes CN with fixed headstock : DMG Mori, Okuma, Index, Miyano

- Bi-Spindle CN with fixed headstock : Index, Okuma, Muratec

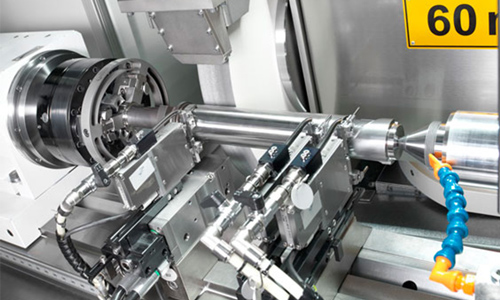

Machining

- Monospindle lathes CN vertical : Emag, Index

- Monospindle lathes CN Front : Okuma, Muratec

Milling

- Machining Center 5/6 axes : SW, Robodrill, Topper, Chiron, DMG Mori

Grinding

Centerless Grinding

- Centerless in-feed: Lidkpoing, Rossi, Herminghausen

- Centerless Diving : Ghiringhelli, Microrex

Cross-point Grinding

- Tschudin

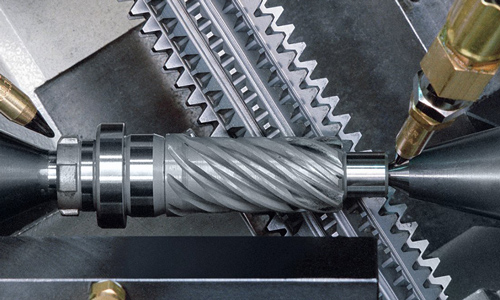

Toothing Grinding

- Gleason

Came Grinding

- Rectifieuses non cylindriques: Junker

Resumption of Machining

Broaching

- Forst, Arpini, Smoc

Cutting

- Gleason, Profilator Wera

Rolling

- Escofier, Peewee

Turning

- Miyano, Index

Induction hardening

- EFD, Emag Eldec

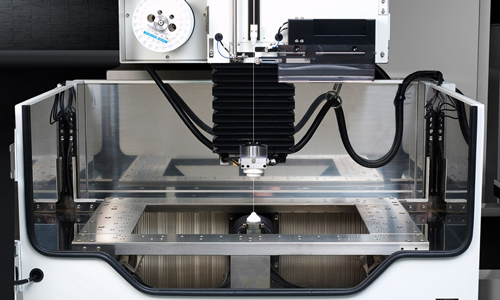

Tools

Wire-Cut Electric Discharge

- CNC Wire-Cut Electric Discharge Machines: Fanuc

Cutting and Sharpening

- Cutting and sharpening center 5/6 axes: Rollomatic, Saacke

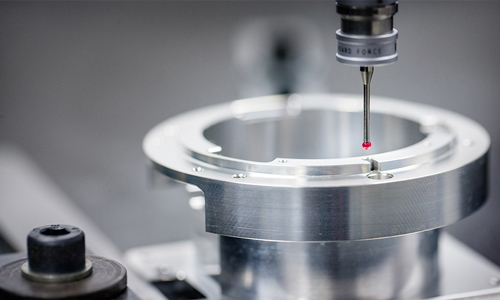

Quality

Quality Control

- Control Machines: Mitutoyo, Keyence, Exameca, Vicivision, Gleason

Automatic Sorting

- Automatic sorting machines: Deltavisione